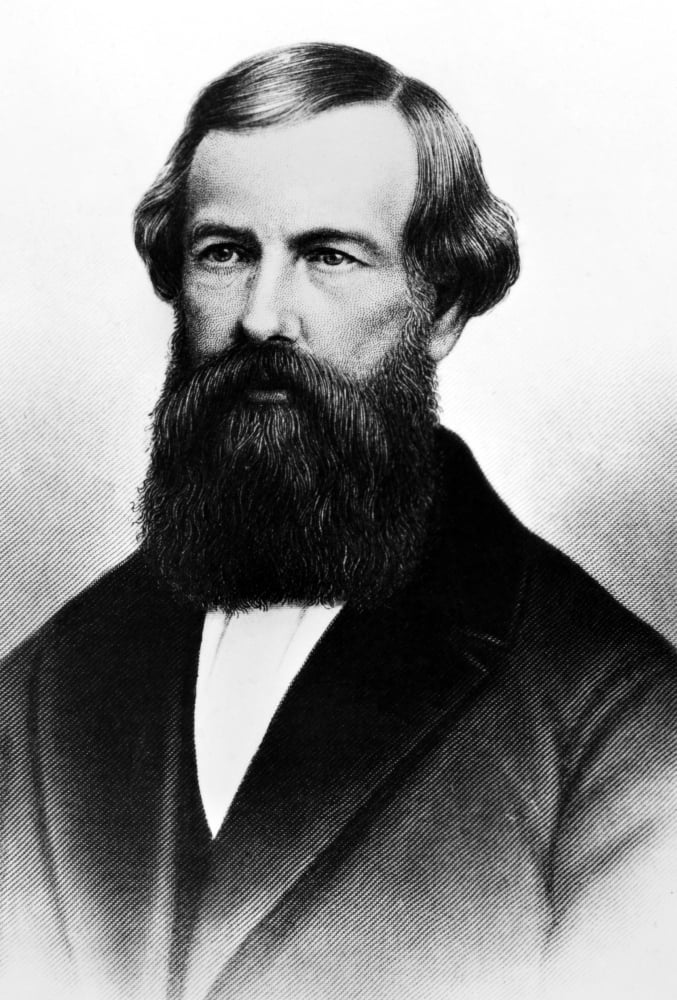

Implementing this practice saved the Stamp Service a great deal of money. Then he realized a better idea was just to print new dates on stamps rather than use new ones. At age 17, he came up with the idea of creating embossed stamps to use on title deeds. The first to develop a process for mass-producing steel inexpensively, this son of an engineer was a prolific and diverse inventor throughout his life. “Man of Steel” Henry Bessemer was born on Januin Charlton, Hertfordshire, England. Celebrating Garey High School InvenTeam's Patent Award!.2023-24 InvenTeam Grants Application Open!.In 1879, Bessemer received a knighthood for his contributions to science. Technology based on Bessemer's technique is used to make modern steel. Later, he attempted to resolve the problem, and with a few tweaks, he was able to achieve success. When Bessemer first developed the extraction technique, he ran into a problem: he couldn't separate the sulphur and phosphorous impurities from the mixture.

He found up a solution to decrease labour and improve accuracy in manufacturing. Wrought iron production at the time was a time-consuming, labor-intensive process that required human slag removal and left certain impurities even after the process was completed implementation. Cast iron is made by processing iron ore with coke, while wrought iron is made by removing impurities from cast iron. "A decarbonization process utilising a blast of air," Bessemer patented in 1855.ĭuring his time, there were two types of iron: cast and worked. Kelly was obliged to sell his invention to Bessemer, who had been working on a similar steel-making technique, due to bankruptcy.

The pneumatic process of steelmaking was invented by an American, William Kelly, who obtained a patent for "a mechanism of air blowing the carbon out of pig iron." To oxidise and eliminate undesired impurities, air is pushed through molten pig iron. Sir Henry Bessemer (1813-1898), an Englishman, developed the first mass-production steel method.

0 kommentar(er)

0 kommentar(er)